Areas of application

Gate wicket

Precise frame geometry. Easy 90˚ cutting of the T-profile

Sliding gate frame

You can cut the T-profile at a slightly wrong angle and the geometry will not be affected

Fence frame

Precise frame geometry thanks to the T-system

Swing gate frame

Torsion-resistant and lightweight - advantages of the T-system for gate frames

Suspended structure frame

The lightweight frame thanks to the T-system guarantees reliable operation for a long time

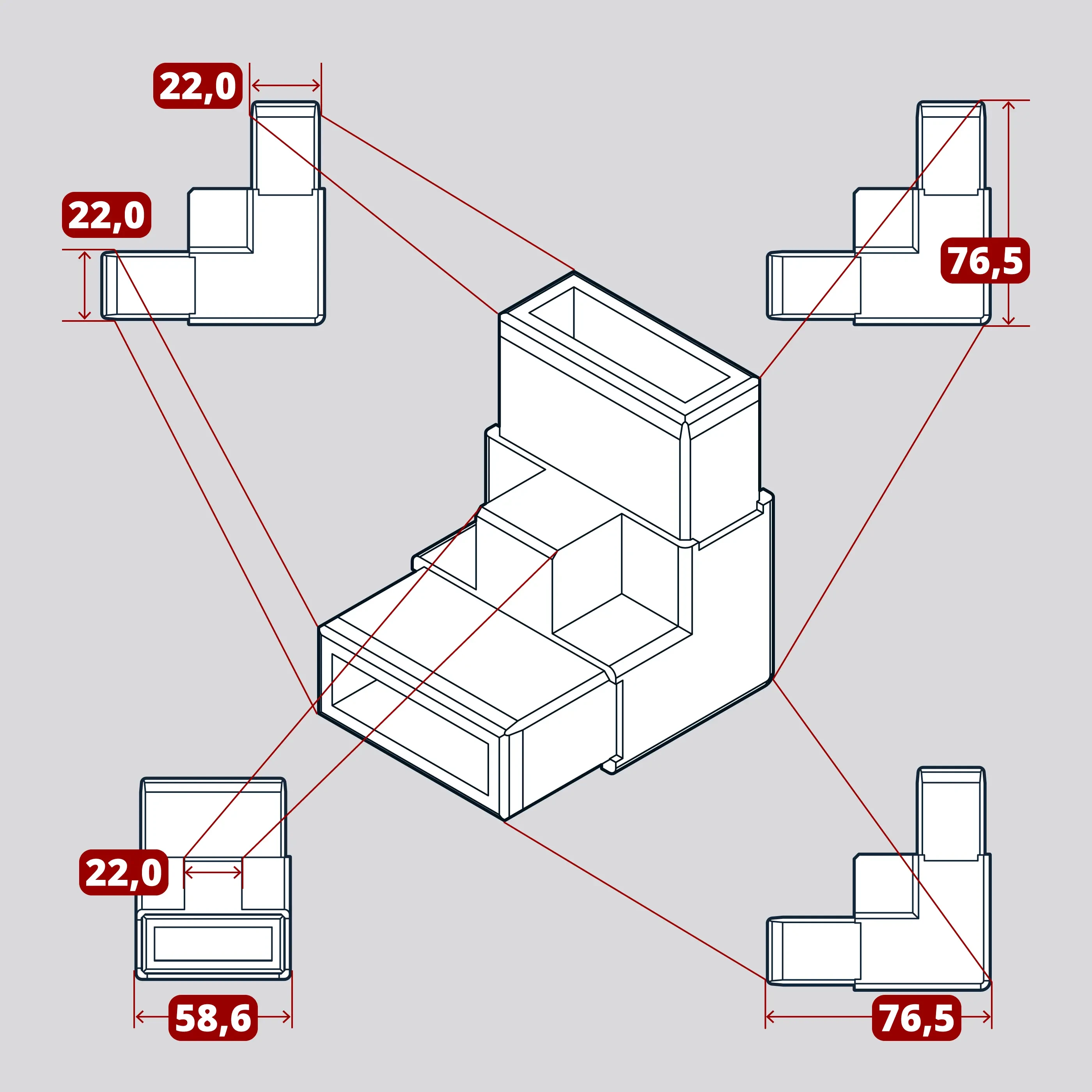

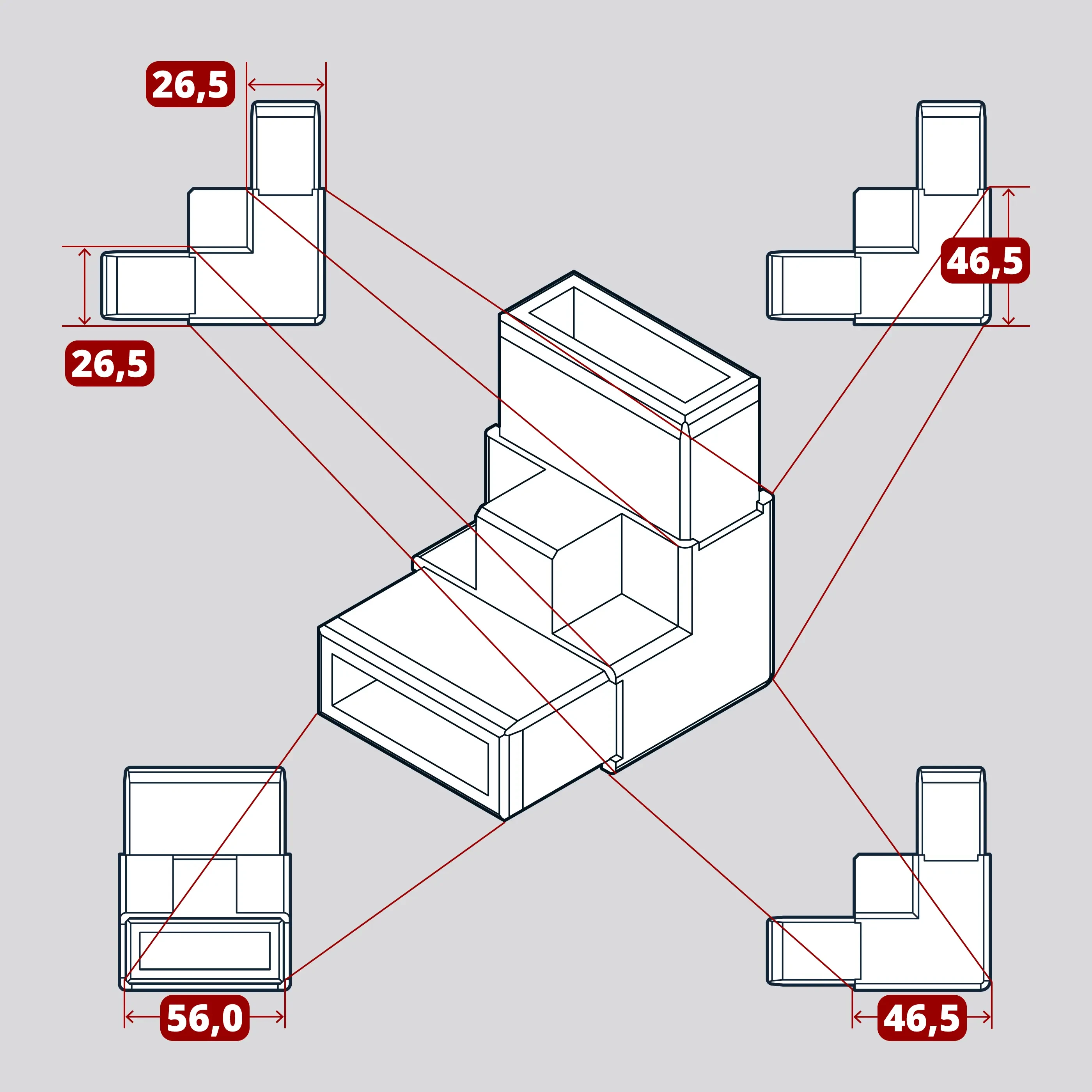

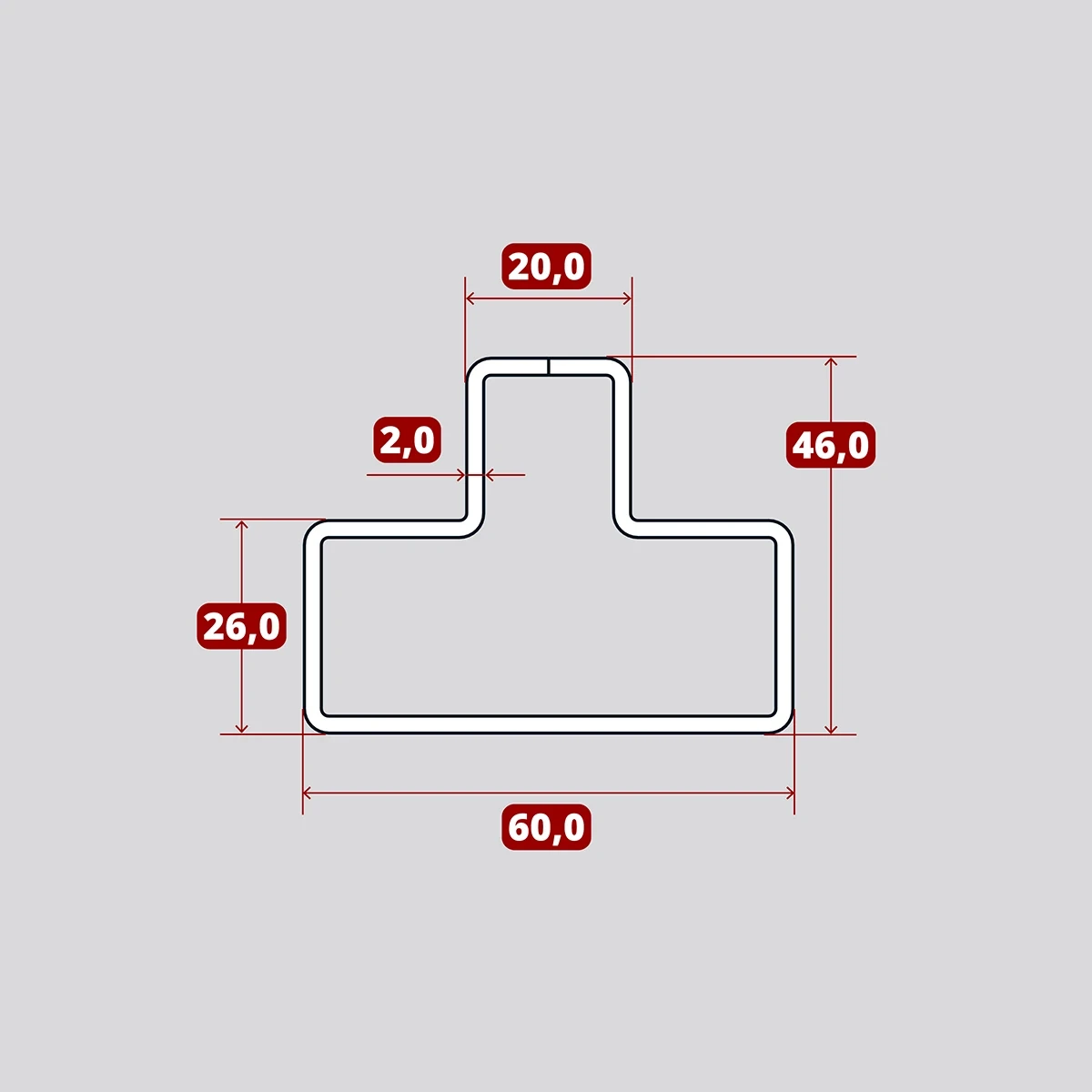

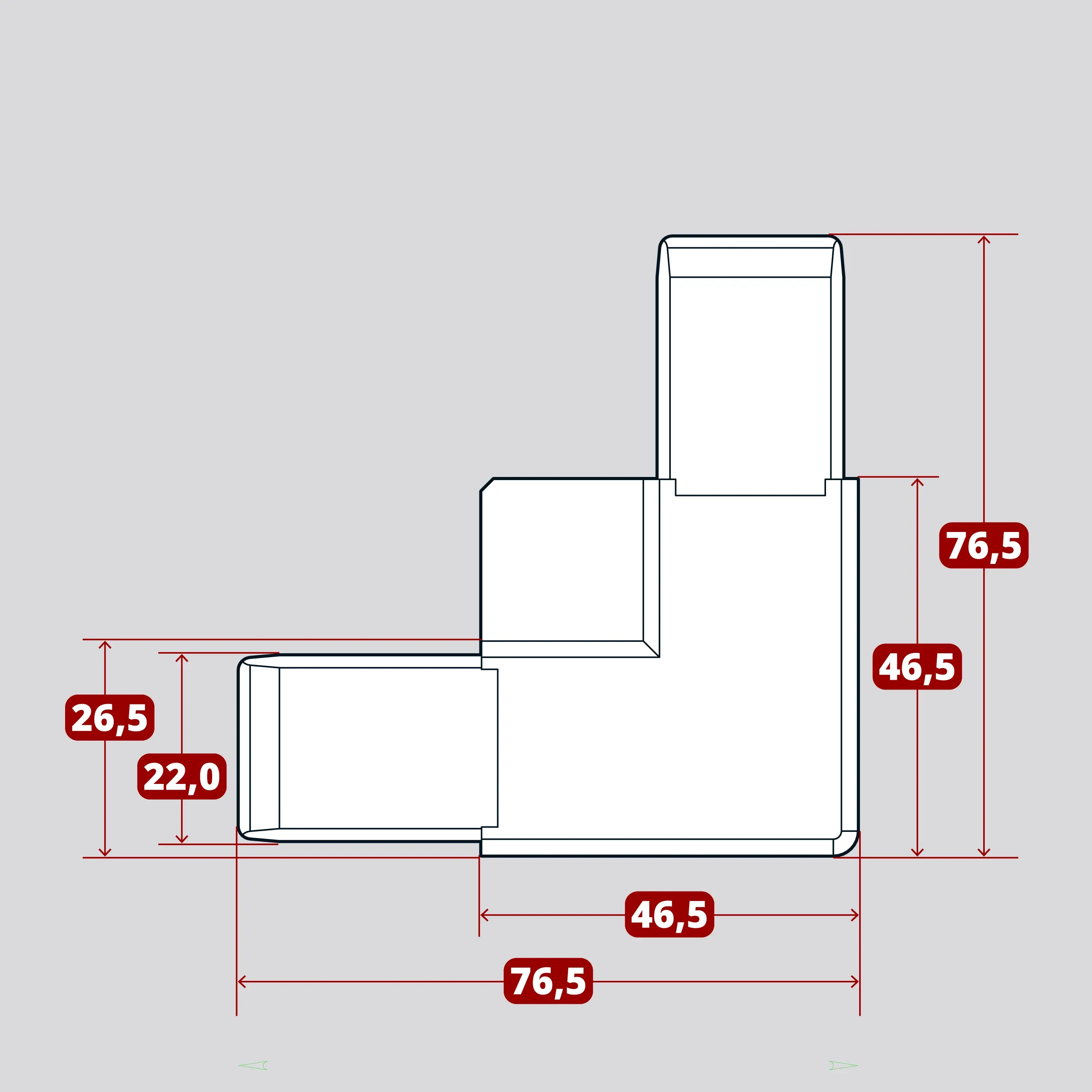

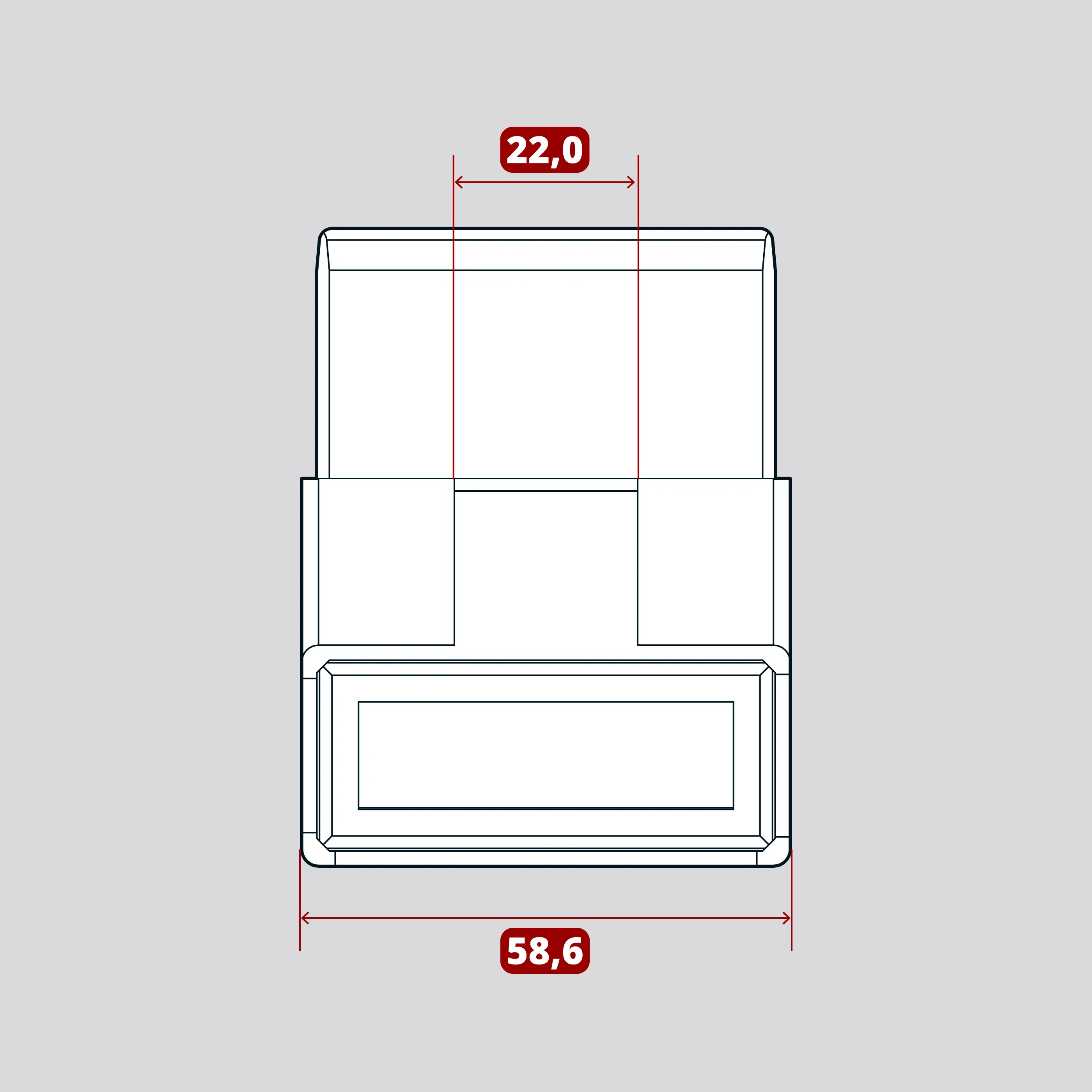

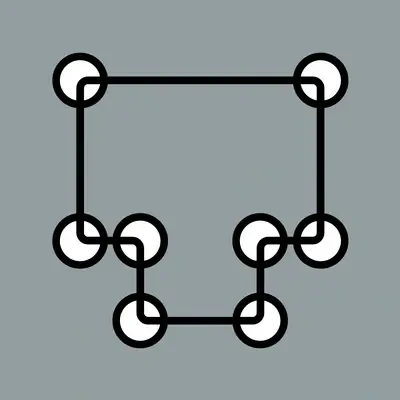

Drawing of an angular T-connector and T-profile

* — actual dimensions may vary within the relevant tolerances

6 advantages of the «T-system»

T-systems from existing solutions in the industry

Lightweight

With the same strength, the T-profile and T-connectors are 31% lighter than conventional profiles welded together, such as 60×40 and 20×30 mm profiles.

Easy to work with

Cut the T-profile, insert it into the corner T-connectors and you will immediately have a 90° corner connection

Easy to weld

Simply connect the T-profile to the T-connector and easily weld the joint along the welding groove.

Cost savings

Both in terms of working time and the quantity of consumables, the T-system is significantly more cost-saving than conventional solutions

Reliability

The T-profile's 8 right angles ensure resistance to torsion and other deformations

No rust

Made of S235JR steel according to EN 10025-2 standard, providing excellent corrosion protection

T-profile — 31% lighter with the same strength

By developing our own T-profile geometry, our company has successfully reduced the metal usage while maintaining the overall structural strength at the required level. This achievement is attributed, in part, to the fact that the strength of the gates is ensured by a well-assembled truss system consisting of gate frames or infils.

Hot-rolled, etched and passivated T-profile metal is practically not subject to corrosion

- No need to remove rust.

- The gate will last longer. The protection of internal cavities is much more reliable.

- Our profiles can be stored in open areas. We use structural hot-rolled pickled and passivated steel grade S235JR in accordance with EN 10025-2, which offers the best corrosion protection. Our regular customers are familiar with this situation from our hardware and guide track for sliding gates.

Easier to mark, cut, assemble and paint

- By using the T-connector, you can cut at a right angle without the need to cut the T-profile at a 45-degree angle or make intricate miter cuts.

- By using a T-connector, you get an additional 90 mm of extra length, which optimises cutting and waste.

- You only need to mark and cut the T-profile twice, rather than four times as required for 60x40 and 30x20 (20x20) pipes.

- The T-connectors allow you to assemble and align the gate frame or panels without the need for an additional assistant. There are no issues with temporary braces, and the angles can be perfectly aligned.

- Preparation for painting is much simpler. The T-profile does not require rust cleaning or pre- and post-welding treatment like in traditional methods. There is also no need for sealant application at the joint of two profile pipes as in the traditional technique.

- It reduces the surface area that needs to be treated with solvents and primers by 31%. The gate frame does not have hard-to-reach areas like welded rectangular profiles of 60x40 and 20x30.

- The T-system is an eco-friendly solution as it reduces environmental emissions, including the release of organic solvents. Less metal, fewer paint materials, and reduced welding work contribute to its environmental benefits.

The welding process in the T-system is simpler and of higher quality

- No rust, no need for edge preparation, and higher quality weld joints.

- The T-system is compatible with both manual MMA and semi-automatic MIG/MAG welding.

- The recommended electrode type is ANO-21 (AWS E 6013). The recommended current is 70-90 A.

- Working with the T-system is accessible even for novice welders. The T-connector is a solid and robust component, reducing the risk of burning it during the welding process.

- The T-connector serves as an ideal reinforcement for attaching gate hinges or braces.

- The weld joint preparation is simplified, making it easier to achieve a high-quality weld.

You save on every transaction

- Less time, effort, tools, and electricity spent on welding/cutting/grinding/priming/painting.

- Less waste compared to traditional technology.

- With the T-profile, the consumption of sealant, primer and paint is lower.

Higher reliability of the gate

- The gate hardware carriage bearings will last longer because they experience less stress due to the lighter weight of the frame.

- Gates/braces made from T-profiles are easier to open/close, both manually and with an electric drive.