The journey of SP Premier Company in the segment of sliding cantilever gates began back in 1999 with the installation of the first cantilever gates.

- 2005 - assembled the first kit of gate hardware.

- 2014 - established the production of cantilever beams on our own rolling mill, the design of which was developed in-house.

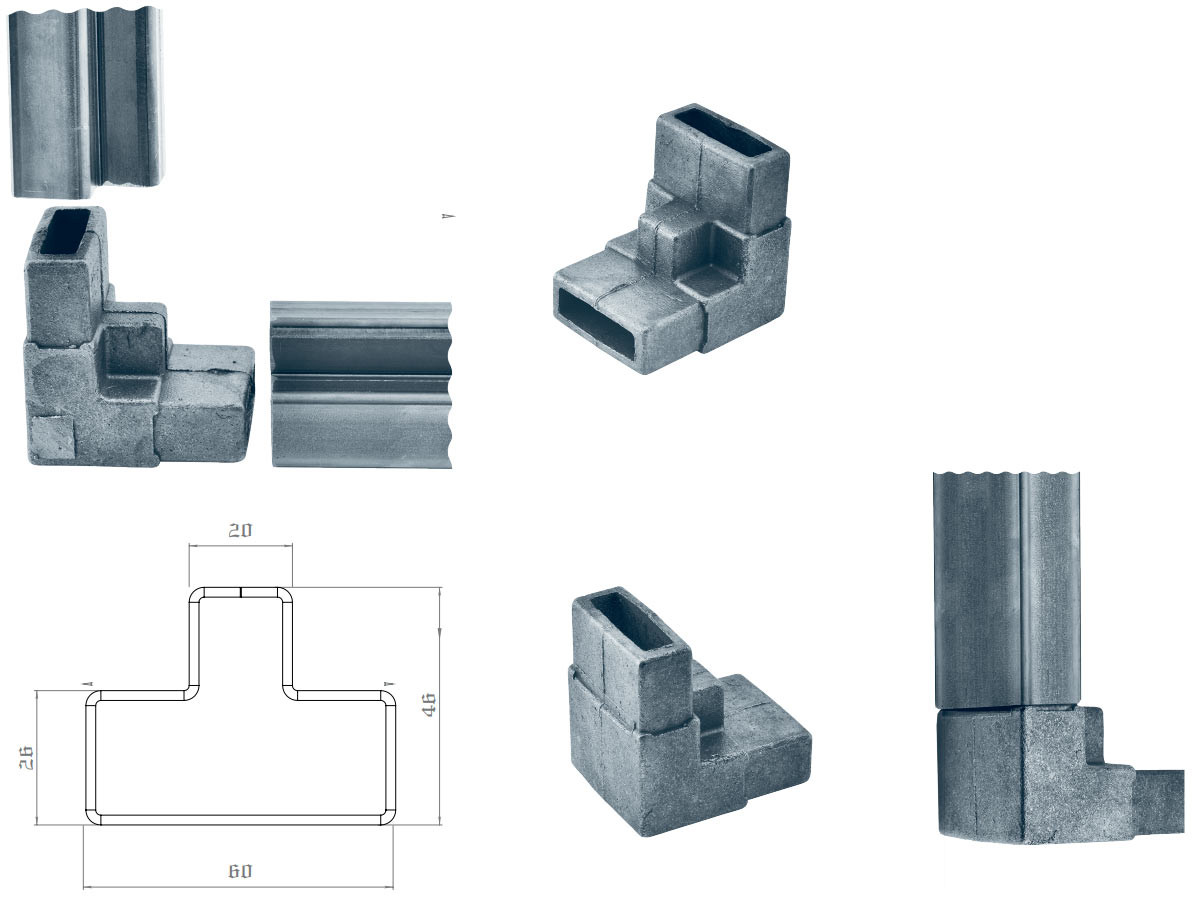

- 2020 - developed the SP Premier T-system and launched its production. This unique development consists of T-profile and T-angle, allowing convenient 90-degree connections.

- 2021 - launched the production of ready-made galvanized gate frames and Self-assembly kits (SAK) in mass production.

Currently, SP Premier has its own technology and a complete production cycle of hardware, materials, and components for sliding cantilever gates.

This contributes to fulfilling the mission of SP Premier Company to increase the accessibility of quality products and solutions at a balanced price, providing a positive experience to our consumers throughout the lifecycle of our products.

Areas of activity of «SP Premier» Company:

Manufacturing:

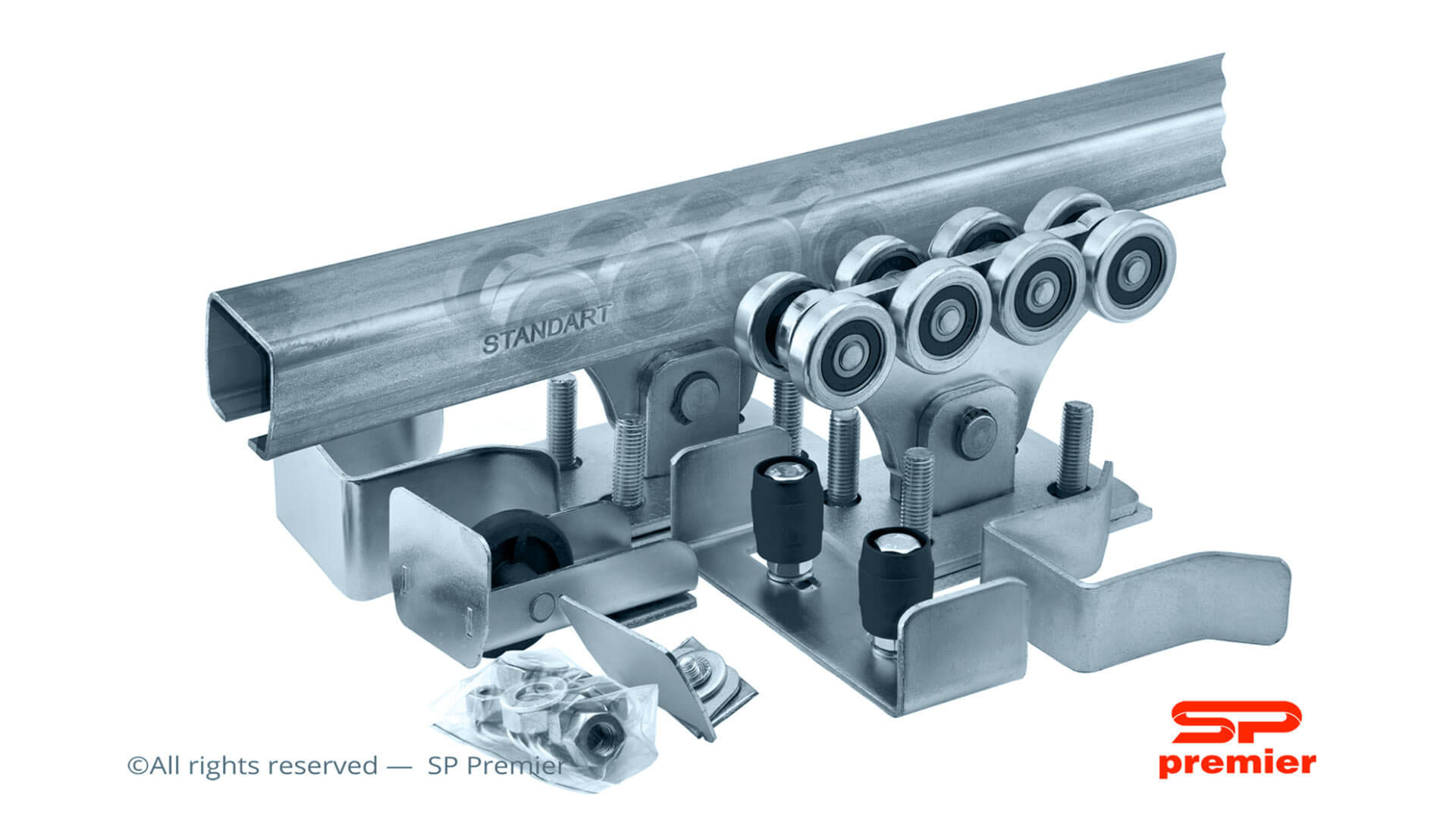

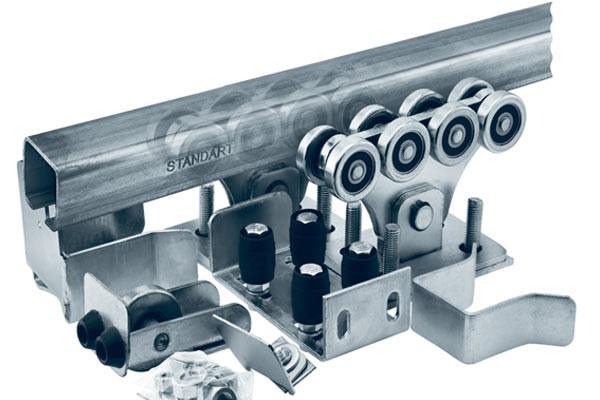

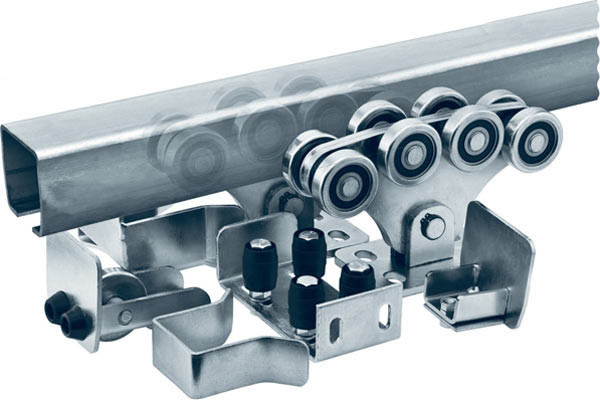

- Kits of hardware for sliding cantilever gates.

- Gate materials presented by the T-system with T-profile and T-angle.

- Industrial suspension system for regular conditions and high-temperature environments.

- Ready-made galvanized gate frames.

- Custom gate frames.

- Boat trailers.

- Screw piles «geoscrews».

Services:

- Foundations and other engineering solutions using geoscrews.

Differences of «SP Premier» Company's Products

The range of hardware, materials, and components for sliding cantilever gates by «SP Premier» Company is created to meet the expectations and needs of our customers in all price segments, from budget to premium.

SP Premier company uses hot-rolled pickled and passivated structural steel of European quality standards.

The steel grade is S235JR according to European classification.

- This provides the calculated modulus of elasticity and load resistance. The passivation of steel significantly enhances corrosion resistance.

- Simplifies storage, including in open areas.

- Speeds up preparation for painting in any way.

Our products stand out with

- Availability of a state certificate of conformity UA0.YT.081308–21.

- Option to choose a solid guide track or a kit for gates of 5, 6, or 7 meters.

- Impeccable geometry of guide tracks.

- Use of solid plate roller carriages in both small and large hardware. This elevates the strength of our products to an unbeatable level compared to competitors.

- Availability of Standart Trend 2 and Standart Pro 2 kits for gates with full counterbalance. Sliding gates with full counterbalance are the gold standard of quality as they withstand wind loads better.

- High-quality bearings of the 201, 301, and 303 series with rubber-metal seals that contain low-temperature consistent grease.

- Safety upper and lower catches with wide 4 mm steel shelves.

- UV-resistant and low-temperature-resistant dual-layer supporting rollers that do not harm the gate coating.

- Reliable metal plugs with a convenient mounting method.

- 20 mm diameter carriage-to-base connection pin, combined with 8 mm thick ears, ensures reliability and longevity of one of the key connections.

- Trademark labeling of products for protection against counterfeiting.

- Gate coating protection and noise reduction with the help of SP Premier Smart Kit, available in high-level hardware kits or as an option.

Product Line of «SP Premier»

SP Premier kits for sliding cantilever gates.

The gate frame is manufactured using European technology. In Europe, structures are usually galvanized before painting, where the color plays only an aesthetic role. Zinc provides protection against rust.

SP Premier medium kits for sliding cantilever gates weighing up to 800-1000 kg.

Ready-made serial galvanized SP Premier gate frames.

SP Premier kits for sliding cantilever gates "Self-assembly Kit" (SAK) that are produced in series.

SP Premier T-system

The SP Premier T-system includes:

- T-profile of unique geometry.

- T-angle

This unique solution, developed by our specialists, is designed for the production of gate frames, hinges, fence sections, and more. It significantly reduces time and material costs while improving the quality and lifespan of the finished products.

As a result, there is no need for additional equipment such as a welding table, clamps, or a miter saw for cutting the profile at a 45-degree angle. It also saves materials for welding, painting, and applying sealant to the joints.

SP Premier T-angle has notches for a face weld.

Therefore, the use of the T-system leads to significant cost savings and contributes to environmental conservation.